On Rising Fuel Costs and New Emissions Regulations

Published: October, 2003

The cost of fuel is rising. OPEC is again looking to reduce production to keep the prices up and climbing. People hunt for stations or marine fueling sites that have fuel of any kind under $2 a gallon. Trucking companies can go out of business with a 25-cent hike in fuel cost. Ferries and all forms of public transit are no exception to fuel hike hardships. The ultimate source of payment is the commuter and consumer.

The Environmental Protection Agency and the Office of Management and Budget jointly drafted new, more stringent rules to reduce dangerous emissions from gas and diesel-powered cars, trucks, vessels, and all other combustion engine equipment. New laws and regulations are to be phased in between now and 2007, with completion scheduled for 2010. The SF Bay Area joined others to experience pollution alerts asking people not to drive cars or run machinery unless necessary and stay indoors if possible this summer. Solutions looked at so far are very expensive, but loss of life costs so much more. The old and young are the most endangered. Can we wait, really?

Washington Post, 12/ 30/02

"The Bush administration is preparing new restrictions on life-threatening emissions, …effecting off-road vehicles, bulldozers, tractors, irrigation machinery and other diesel-powered equipment. The proposed rules would slash off-road diesel emissions by as much as 95% percent bringing them in line with newly adopted standards for heavy-duty diesel trucks and buses that traverse the nation’s highways. After power plants, off-road diesel engines are among the largest source of pollutants scientists have linked to premature deaths, lung cancer, asthma and other serious upper respiratory illnesses. The proposed rules would save an estimated 8,300 lives a year and tens of billions of dollars annually in medical costs and lost workdays. … January 2001, EPA approved a Clinton Administration rule requiring swift and sharp reductions of as much as 95% percent in emissions of particulate matter and nitrogen oxides from large diesel-powered trucks and buses beginning in 2007. An interim ruling to reduce sulfur also begins …in 2007 with full compliance required by 2010."

Baltimore Sun, 12/13/2002

Better Mileage required for SUVs and Pickups. (1.5 miles-per-gallon increases over 3 years). "The Bush administration approved a modest increase in fuel economy requirements for sport utility vehicles and small trucks …(car companies are) beginning with the 2005 model year."

"Maryland Transit Authority buses burn 7.8 million gallons of diesel fuel per year, adding to the regions poor air quality and contributing to health problems such as asthma and cardio-vascular disease, scientist says. The Citizens Planning and Housing Authority estimates it will cost between $5 million and 8 million to add the particulate-matter traps to the buses and an additional $1 million in fuel cost to switch to ultra-low-sulfur diesel."

San Jose Mercury News,

12/12/98

Representatives of the marine industry said, "The cost of modifying marine engines to comply with the new regulations is higher than the board’s estimates." The board said altering an engine would add an average of 14 percent to the cost, which would be passed on to consumers. The engines range in price from a few hundred dollars to $20,000. Jay, a Milpitas boat retailer, said the new regulations are "just too costly. It’s as if they are going to intentionally regulate me out of business."

By applying a basic principle of physics, a new product has been developed by a brilliant man, Richard Hricak. Richard invented safety glass by putting a film between the glass and colored film that reduces UV damage. His new product for all types of combustion engines is now available. His new company, EcoNet International Corp., produces an engine product available to purchase or rent for far less than any other solution offered to help resolve the pollution crisis by emission reduction, allowing immediate steps to reduce emissions and cut fuel costs. After more than ten years of research, he has developed and patented the system. It is simple with no moving parts, easy to install on any engine, and does not affect warrantees. It substantially reduces harmful emissions, such as hydrocarbons, nitrogen oxides, sulfur, diesel particulate matter and carbon monoxides, plus it boosts engine power while saving 12 percent to 25 percent (and more in some tests) on fuel costs and reduces long-term maintenance expense. It works!

How Does It Work?

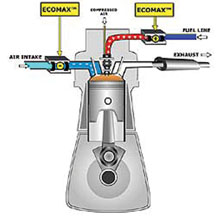

The ECOMAXtm system works on a simple principle of physics. Hydrocarbons (fuel) and Oxygen (air) molecules are naturally negative in the northern hemisphere and positive in the southern hemisphere. The new ECOMAXTM system, released just six months ago, super charges all the molecules with polarities that work together. In a combustion engine, naturally negative polarity of fuel is changed to positive so air and fuel will bond with each other rather than repel due to like polarities. They then work together to provide higher efficiency and dramatically reduce the escape of unburned, wasted fuel into the atmosphere.

"Monopole Compression Technology" developed by EcoNet International Corporation reinforces the negative charge of the air polarity to achieve more effective results. When ECOMAXTM positive fuel molecules meet ECOMAXTM reinforced negative air molecules in the combustion chamber, they attract and bond and 30 percent more fuel is used instead of that same percentage of unburned fuel escaping blackening the exhaust. Unburned fuel is the major source of sulfur in the exhaust. Using ECOMAXTM provides "additional" fuel in this way. More fuel is used instead of going up as smoke. It saves money, saves lives, and takes a big step toward meeting emission standards affordably.

Paired ECOMAXtm units are clamped to the fuel line, starting from the fuel injector rail, spaced at a prescribed distance of (6 inches) from each other back toward the tank, giving the fuel maximum exposure to change its polarity from negative to positive. This part of the technology was first developed in Germany more than 20 years ago. "A fuel line treatment product has become a standard for all commercial trucks and public buses and for private use like high performance cars in England. My father (a doctor in England) has a high performance car and transfers his unit from his old to his new car himself and has for many years to reduce fuel cost and improve performance." said Richard Maguire of Stone Boat Yard. So what is so new about ECOMAXTM? ECOMAXTM is the result of development of the whole idea. It also adjusts size and number of units to match the size of engine for maximum effect to change fuel polarity fully and combines with paired units securely fastened to the air intake to reinforce air’s natural negative charge. There is also a coolant line unit that rids the system of scale from the inside of the radiator or water pump boosting power. Each millimeter of scale reduces engine performance by 5 hp. To complete the cycle and further reduce emissions, a last unit is securely fastened to the oil filter casing capturing small particulate matter, less than 25 microns, that wears and tears at the engine. Under 25 micron particulate matter that escapes in the exhaust has been determined to be a major contributor to death from lung and heart disease.

Richard Hricak, the inventor, said in an interview, "We can adapt this system to any size engine with specific information. All we need to know is the material the fuel tank is made of, the length and diameter of the fuel line and the length and diameter of the hoses." Richard was very enthusiastic to adjust their calibrations in their computer models to produce units to work on marine and other engines of sizes other than those seen on their website which address primarily cars and trucks. "The power of our system is in its simplicity. Our units, which can be created to work with any size engine, only take approximately 45 minutes to install in most cases, and do not require any special tools, only special knowledge. We share that knowledge once an engine is surveyed, at no charge, for exact locations and prescribed distances between units per engine type so new unit owners can there after do their own installations for new kits purchased for their fleet or if they transfer a kit from an old engine to a new one."

EcoNet Intl. Corp. guarantees the system for a minimum of five years or your money back! These units work on gas, diesel, alcohol, methane, or any type of combustion engine. It is in trial and being purchased for a number of applications across the country including our local Golden Gate Transit commuter bus system. Three Golden Gate Transit buses are testing the units. So far, the tests are proving the companies claims. Testing is in the planning phase for a number of other cities and metropolitan areas for commuter buses plus trucking companies and major retailers are showing strong interest. Two unique uses are a pair of methane generators used to reduce power costs for a Visalia agricultural group and an East Coast mineshaft air circulator engine changed its exhaust from black to white the first day. Test results can be seen on their brochures and on their website.

So what is the bottom line for projected savings in dollars and cents? Their graphs show saving variations depending on the number of miles or hours an engine is used per year. The range is $210-$21,000 for diesel and $318-$9,545 for gas, showing the least reported improvement of 5 percent to a modest high of 25 percent. The only misleading aspect to the graphs is the price of gas and diesel used to formulate savings. The ECOMAXTM graphs reflect savings based on $1.15 for diesel and $1.40 for gas. Remember those days? Savings from this device has grown accordingly. In addition to fuel cost reduction, savings are also realized by lowering engine maintenance expense. The ECOMAXTM reasonably priced units range from $285 to $895 for cars, trucks, and buses. Complete kits pay for themselves in fuel savings alone in a matter of months. EcoNet representatives work with companies to provide test units or units for sale for all engines and can provide sizes and types not shown.

"It has been said that you can lead a horse to water but you can’t make him drink! EcoNet International Corp is aware change is difficult so they are "salting the hay" by offering free installation on up to three engines for a trial period of five to eight fillups or up to 30 days. The only requirement for a test site prior to installation is that an engine’s emission and fuel consumption has to be established. During the test period, records of mileage at each fillup have to be kept. At the end of the trial period, emissions are checked again. EcoNet Intl. is even acquiring a field test kit to check exhaust emissions easily and affordably. After the tests, there is no obligation to purchase. The exhaustive tests EcoNet have run before release have proved so clearly that the product does what is promises that EcoNet is certain those who try it will agree it pays for itself starting from the first day. EcoNet also offers a rental program, which does not require cash layout for fleets and makes operational expense 100 percent tax deductible. The company is confident that their product will be a cost-effective solution for the national problems of rising fuel costs and soon-to-be illegal hazardoux emissions." Said George Landau, a very successful business consultant who joined EcoNet International’s sales team after seeing this product at its unveiling, "What excites me is its universal application and simplicity. If fuel usage dramatically drops, historically prices will too. If enough fuel users use ECOMAXTM to cut fuel costs, perhaps even OPEC will be affected. It would be good to see $1.40 at the pumps again."

For more information about the ECOMAXTM Systems, go to www.ecomaxtm.com, contact George Landau at 415-435-7051 or e-mail george@georgelandau.com.