The zero-emission passenger vessel that Red & White Fleet President Tom Escher has been dreaming about for the last three years is slated to carry its first travellers on San Francisco Bay by the end of next year.

Alameda-based shipyard Bay Ship & Yacht will build the first hydrogen-powered passenger vessel of its kind in the country, and is scheduled to be operational by the end of 2019.

BY BILL PICTURE

Published: August, 2018

The zero-emission passenger vessel that Red & White Fleet President Tom Escher has been dreaming about for the last three years is slated to carry its first travellers on San Francisco Bay by the end of next year.

The California Air Resources Board (CARB) recently awarded a $3 million grant to Golden Gate Zero Emission Marine (GGZEM) to build a refined version of the SF-BREEZE, the initial hydrogen-powered ship design that Escher and Sandia National Laboratories unveiled in March of last year. GGZEM has chosen Alameda-based shipyard Bay Ship & Yacht as a partner to construct the vessel. Production of the updated design, whimsically dubbed the Water-Go-Round, will begin in the coming months and is scheduled to be delivered to Red & White Fleet by next September.

The Water-Go-Round will be the first vessel of its kind in the country. “You could think of Water-Go-Round as SF-BREEZE Jr.,” said GGZEM CEO Dr. Joseph W. Pratt. Pratt was with Sandia National Laboratories in 2016 when it conducted a feasibility study to determine whether hydrogen fuel cells could generate the horsepower required to move passengers across the Bay. That study was conducted in partnership with the Department of Transportation’s Maritime Administration, the American Bureau of Shipping, the U.S. Coast Guard and the Port of San Francisco.

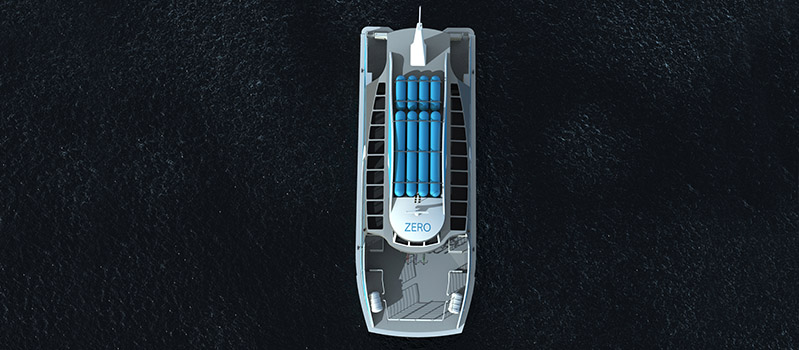

SF-BREEZE, the team’s hypothetical vessel, which was made entirely of off-the-shelf parts, passed every test with flying colors. Pratt took the project with him to Golden Gate Zero Emission Marine when he founded the company earlier this year. Since then, the team has been optimizing the design to come up with a vessel that, as Escher put it, “makes the most economic sense.” A couple changes here and there eventually resulted in the 70-foot-long, all-aluminum Water-Go-Round, which will carry up to 84 passengers at a top speed of 22 knots (compared to SF-BREEZE, which was to carry 150 passengers at a top speed of 35 knots).

Building the now-optimized Water-Go-Round is also expected to cost a fraction of what SF-BREEZE would have. Pratt expects that the $3 million grant, which CARB announced last summer was up for grabs to cover off-road passenger transport projects, including rail and ferry, will cover a “big chunk” of that cost.

Keeping it local

Bay Ship & Yacht was the obvious choice to build Water-Go-Round, Pratt said. Its proximity will allow his team to swing by the shipyard whenever they want to watch their baby take shape, and he says he’s proud to support a company that’s continuing the Bay Area’s rich shipbuilding history. “And we have a real affinity for showcasing the Bay Area as the leader in green technology, innovation and learning,” he added.

“We’re so happy and proud to be a part of this,” said Bay Ship & Yacht Director of Business Development Richard Maguire. “It’s not very often you’re given the chance to be the first at something—much less the first in the country.”

Over the years, repairs have become Bay Ship & Yacht’s main focus, so Maguire said his team is particularly excited to have this opportunity to build a vessel from scratch. “A few years ago, I thought, ‘Why aren’t we building anything anymore?’” he said. “And I made a vow then to market the company to be a part of the future, where I knew there would be more building opportunities. This is the future.”

Likewise, GGZEM hopes to position itself as a go-to for ferry and charter tour operators interested in zero-emission technology for both new and existing vessels. GGZEM will continue to develop and sell the drivetrain technology, and a shipbuilder will handle it from there. So this aligning of the two companies’ shared vision of the future of the maritime industry appears to be the start of a meaningful and beneficial partnership.

“Refurbishment is still the most viable option for a lot of ferry operators,” Pratt said. “But that’s changing.” Hydrogen fuel cell technology reached maturity in the 1980s, according to Pratt; and since then, he said researchers have been working to find a way to make the technology more affordable. “Smaller, lighter, cheaper,” Pratt said. “And now we’re at the point where we can see the cost trajectory of fuel cells dropping, so now is the time to establish ourselves as the market leader.”

Given the rising price of diesel fuel—the Department of Energy projects a 19-cent increase annually per gallon—operators’ bottom lines depend on finding ways to cut costs. Pratt said that while the cost to build a new vessel or refurbish an existing one comes off the top, so to speak, that operator is insulated from fossil fuel costs that can put a company in the red.

“It makes for better financial planning because you’re projecting a stable fuel cost over the lifetime of your boat,” Pratt said. “And ‘operating cost’ really combines fuel and maintenance.”

A hydrogen-powered vessel is also cheaper to maintain because an all-electric drive train has a half-dozen moving parts compared to hundreds in a diesel engine. “Fixing something will mean removing a dead cell and popping in a new one,” Pratt said. “No down time; and you won’t call a mechanic, you’ll call an IT guy. The savings are going to be huge.”

“I’m taking a crash course in IT right now,” joked Maguire, who said he also sees an opportunity to generate new interest in the shipbuilding profession. “A lot of people think of it as an archaic business, and I’m hoping this will help attract new talent,” he said.

Red & White Fleet will test drive Water-Go-Round for three months before adding the vessel to its fleet. During those three months, CARB and Sandia National Laboratories will monitor its performance closely. “The state wants to determine whether or not hydrogen fuel cell technology is viable for maritime applications,” Pratt said. “We did the feasibility study so we know the answer, of course.”

Before leaving Sandia to start GGZEM, Pratt actually looked into whether fuel cell technology could be applied to even larger vessels. “We looked at everything from fishing boats to the largest container ships in the world to see if there was a limit, and we never found it—because as the ships get bigger so do the engine rooms and the fuel tanks. We could virtually take out existing engines and engine room and fuel tanks and replace them with enough hydrogen fuel cells and liquid hydrogen tanks to power the ship.”

Nevertheless, Pratt said he’s happy to indulge the folks in Sacramento. “No one really believes it until they can see it and touch it and ride it for themselves,” he said. “I get it. And If this allows them to start including hydrogen fuel cell technology as eligible for incentives, I’m game.”

Engineering renderings furnished by Incat Crowther

The 70-foot-long, all-aluminum Water-Go-Round will carry up to 84 passengers at a top speed of 22 knots.